The SimulationObject Data Structure as Enabler for a Service-Oriented Architecture for Simulation-Based work flows

A complex system that works is invariably found to have evolved from a simple system that worked. A complex system designed from scratch never works and cannot be patched up to make it work. You have to start over with a working simple system. – John Gall: Systemantics: How Systems Really Work and How They Fail

All complex systems are modular and hierarchical – by necessity. – Francois Chollet (creator of Keras) on X

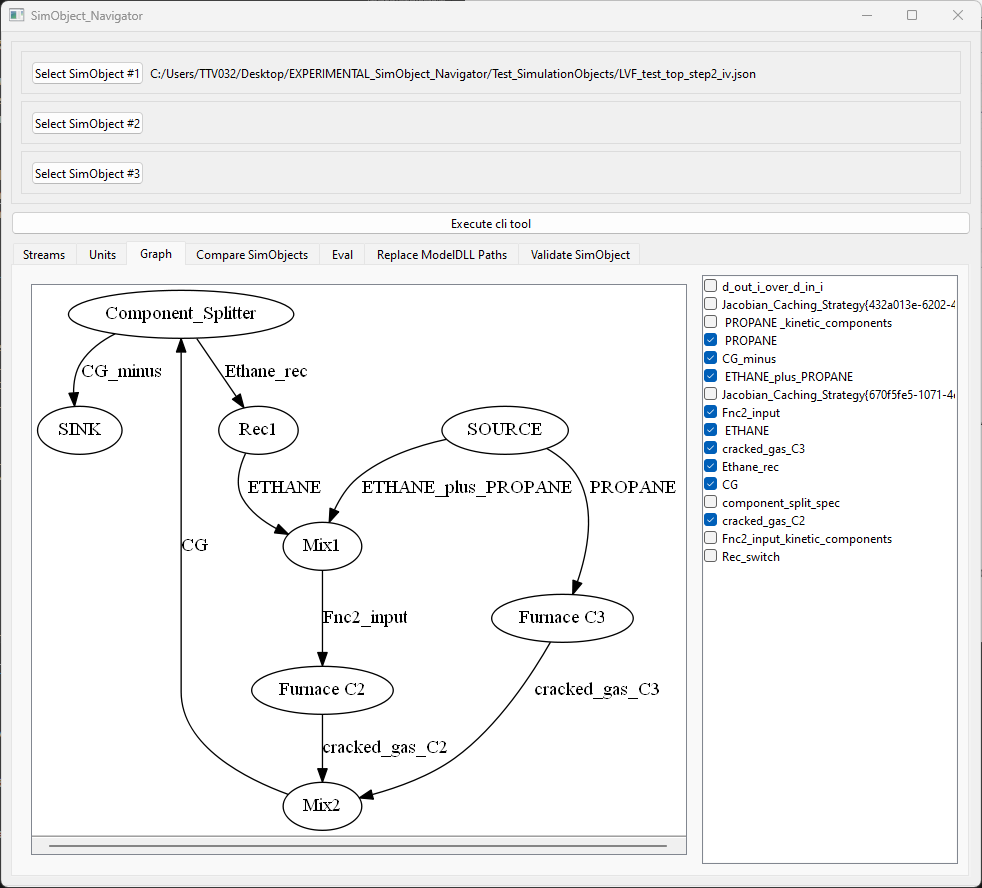

The SimulationObject is a simple data model which describes a simulation task. It describes both the (flow sheet) topology and the physical state of a simulation. Mathematically, it is a directed graph, where the

edges are connectors (=simulation unit inputs and outputs, e.g. a process stream is a connector)

vertices are simulation models (e.g. process units or sub flow sheets)

A SimulationObject describes the flow of mass, energy, information or other quantities between ‘units’ (more generally: mathematical models of technical or physical systems). In our setting SimulationObjects will often resemble flow sheets or simulation units.

The data model is normally serialized as a json string (described by a json schema) - however, high performance implementations relying on gRPC are feasible.

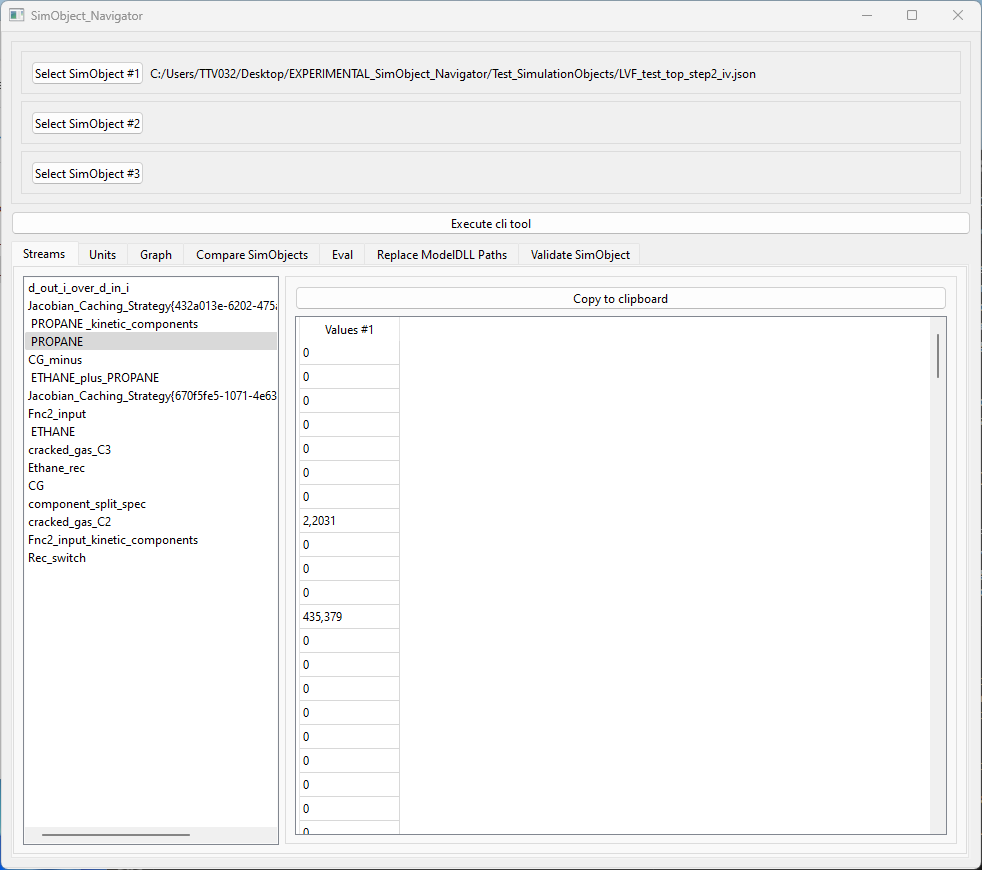

A graphical representation of the contents of a SimulationObject is given below:

Topology:

State:

State:

SimulationObjects may be used to set up systems hierarchically; a heat exchanger used in a SimulationObject may itself be set up from a SimulationObject which sets up a heat exchanger model as a combination of flow passage models, metal capacitor models, heat transfer models and pressure drop models.

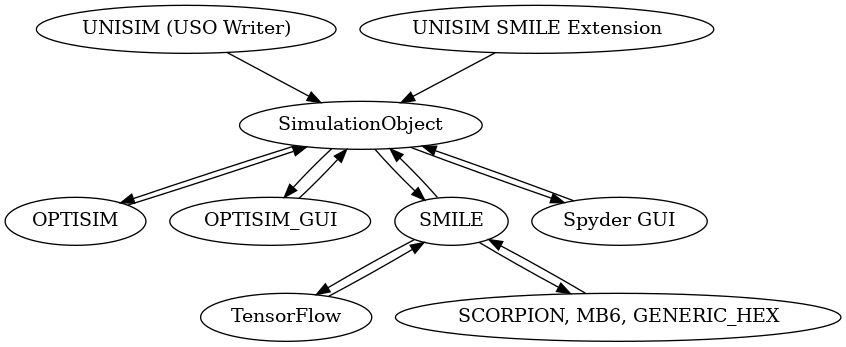

The SimulationObject data model is already supported by a number of ITPP tools (arrows indicate information flow directions):

Why should we care?

The SimulationObject data model is intended to allow for

a client-server architectures for simulation-based work flows, e.g.

OPTISIM \(\leftrightarrow\) OPTISIM GUI, later: OPTISIM GUI \(\leftrightarrow\) SMILE/OPTISIM back end

There is a prototype of SimulationObject-based SMILE Simulation Server.

aligning software components used at ITPx towards more reusability, e.g (Web) GUI components

A PC_VIPS - like generic Process Stream GUI could be implemented as a web GUI, completely independently of the physical property system used

A plot tool to visualize data such as column|membrane|HEX profiles could be set up generically and used in the OPTISIM GUI as well as in the UNISIM SMILE Extension as well as in SMILE’s python interface

A prototype for a SimObject based GUI tool is the Simulation Object Navigator

facilitate outsourcing of components which have only SimulationObject interfaces

simplify integration test

setting up numerical tasks such as fitting compressor maps or physical properties in a (highly) tool-independent way

Example Simulation Object

A json serialization of a very simple SimulationObject reads as

{

"Flowsheet": {

"ddec7d6c-1ff1-495e-8b7e-7422ebf19a40": {

"Name": "sqrt",

"ModelDLL": "Examples/Models[SquareRoot_assign]",

"Ports": {

"V_IN": {

"UUIDs" : [

"74922c22-7988-4165-8fbd-3db07f673c03"

]

},

"V_OUT": {

"UUIDs" : [

"585dd521-f4b7-46a3-9487-4c39b8dcf583"

]

}

}

}

},

"Connectors": {

"74922c22-7988-4165-8fbd-3db07f673c03": {

"Name": "x",

"Assigned": false,

"Values": [

2

]

},

"585dd521-f4b7-46a3-9487-4c39b8dcf583": {

"Name": "y",

"Assigned": true,

"Values": [

1.414213562373095

]

}

}

}